Table of Contents

3D printing, also known as additive manufacturing, has become a transformative force in the field of product design. By enabling the creation of complex, customized, and highly precise objects directly from digital models, 3D printing is reshaping how products are conceived, developed, and brought to market. This article explores the ways in which 3D printing is revolutionizing product design, highlighting its impact on creativity, efficiency, and manufacturing processes.

The Evolution of 3D Printing Technology

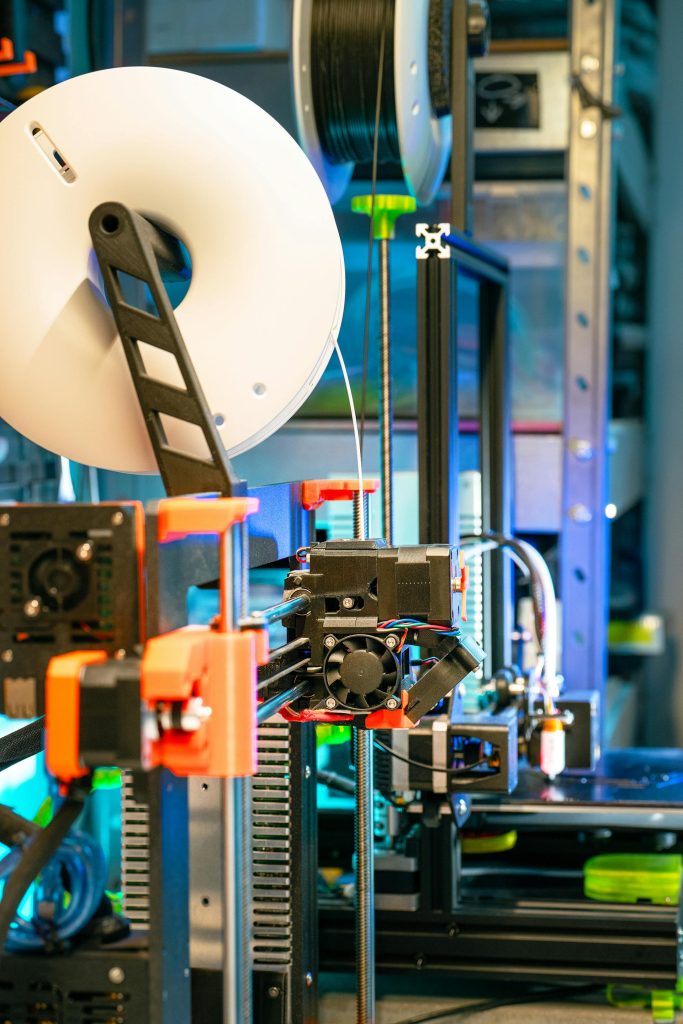

3D printing technology has come a long way since its inception. Initially used primarily for prototyping and rapid design iterations, it now encompasses a wide range of applications across various industries. Modern 3D printers are capable of producing high-quality, functional parts and products using a variety of materials, including plastics, metals, ceramics, and even biological materials.

The evolution of 3D printing technology has been driven by advances in software, materials science, and printer capabilities. Sophisticated CAD (computer-aided design) software allows designers to create intricate digital models with high precision, while improvements in printer technology enable the production of complex geometries and fine details. As a result, 3D printing has become an integral tool in product design and development.

Enhancing Creativity and Innovation

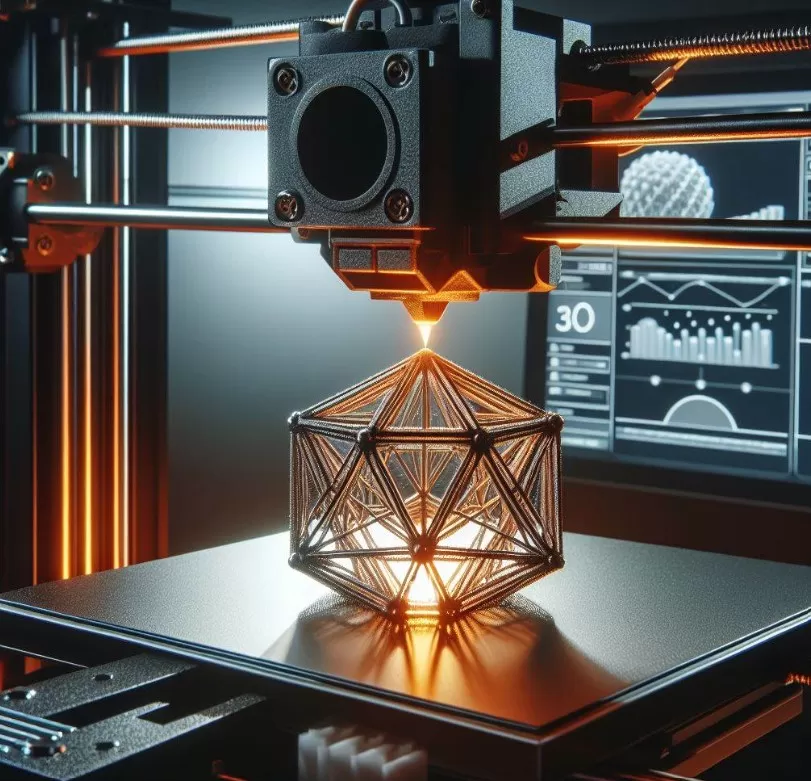

One of the most significant ways 3D printing is revolutionizing product design is by enhancing creativity and innovation. Traditional manufacturing methods often impose constraints on design due to limitations in tooling and production processes. 3D printing, however, offers virtually unlimited design freedom, allowing designers to create complex shapes and structures that would be impossible or prohibitively expensive to achieve with traditional methods.

For example, designers can experiment with organic, fluid forms and intricate lattice structures that optimize strength-to-weight ratios. This level of design flexibility fosters innovation, enabling the creation of products that are not only aesthetically unique but also functionally superior. The ability to quickly prototype and test new ideas accelerates the design process, leading to faster development cycles and the introduction of groundbreaking products.

Accelerating Prototyping and Iteration

3D printing has significantly accelerated the prototyping and iteration phases of product design. In traditional manufacturing, creating prototypes often involves time-consuming and costly processes, such as machining, molding, or casting. 3D printing streamlines this process by allowing designers to rapidly produce physical prototypes directly from digital models.

This rapid prototyping capability enables designers to quickly test and evaluate their concepts, identify design flaws, and make iterative improvements. The ability to produce multiple iterations in a short timeframe reduces development costs and time-to-market, ultimately leading to more refined and effective products. Additionally, 3D printing allows for easy modifications to designs, facilitating a more agile and responsive design process.

Customization and Personalization

Customization and personalization are key trends in modern product design, and 3D printing is at the forefront of this movement. Unlike traditional manufacturing methods that often involve large production runs and standardized designs, 3D printing allows for the creation of highly customized products tailored to individual preferences and needs.

From custom-fit medical implants and prosthetics to personalized consumer products such as jewelry and eyewear, 3D printing enables the production of one-of-a-kind items that cater to specific requirements. This level of personalization enhances user experience and satisfaction, as products can be designed to fit individual specifications and preferences. The ability to offer customized solutions also opens up new market opportunities and revenue streams for businesses.

Reducing Waste and Improving Sustainability

Sustainability is a growing concern in product design, and 3D printing offers significant advantages in terms of reducing waste and improving environmental impact. Traditional manufacturing processes, such as subtractive machining, often produce substantial amounts of material waste as excess material is removed to achieve the final product shape.

In contrast, 3D printing is an additive process, where material is deposited layer by layer to build the final product. This approach minimizes material waste and allows for the use of more sustainable materials, such as biodegradable plastics and recycled materials. Additionally, 3D printing enables on-demand production, reducing the need for large inventories and excess stock, which further contributes to sustainability efforts.

Transforming Supply Chains and Production Models

3D printing is also transforming supply chains and production models by enabling localized and on-demand manufacturing. Traditional supply chains often involve complex logistics, long lead times, and centralized production facilities. 3D printing allows for the decentralized production of parts and products, potentially reducing the need for extensive shipping and warehousing.

With 3D printing, products can be manufactured closer to the point of use, leading to shorter supply chains and faster delivery times. This localized production model not only reduces transportation costs and carbon footprints but also enhances responsiveness to market demand and reduces the risk of supply chain disruptions.

Challenges and Future Outlook

Despite its many advantages, 3D printing faces several challenges that need to be addressed for broader adoption. These include limitations in material choices, print speed, and surface finish quality. Additionally, the initial investment in 3D printing technology and the need for specialized expertise can be barriers for some businesses.

Looking ahead, ongoing advancements in 3D printing technology are expected to address these challenges and expand its applications. Innovations in materials science, printer capabilities, and post-processing techniques will enhance the performance and versatility of 3D printing. As these advancements continue, 3D printing is likely to play an increasingly central role in product design and manufacturing.

Conclusion

3D printing is revolutionizing product design by enhancing creativity, accelerating prototyping, enabling customization, and improving sustainability. Its ability to produce complex, customized, and high-quality products directly from digital models is transforming how designers and manufacturers approach product development. As technology continues to evolve, 3D printing will undoubtedly drive further innovation and shape the future of product design, offering new possibilities and opportunities for businesses and consumers alike.